Got a bit more accomplished this weekend and thought I post a few more pictures.

First up....

The thin sheets of veneer (that are almost five feet long and 22" wide) need to be soaked with a wood softening chemical and pressed. These have been pressed for several days ....granted, longer than needed, but that will do nothing but make our lives easier later down the road. It's hard to press something that large, but the sheets are wrapped in wax paper (so the moisture doesn't get sucked out), then every piece of large plywood I have is placed on top, then all the heavy boxes of speaker parts are placed on them, and finally, a few 2"x4"'s and clamps to squeeze them into submission.

You can see a bit of the veneer peeking out, in the lower left of the photo.

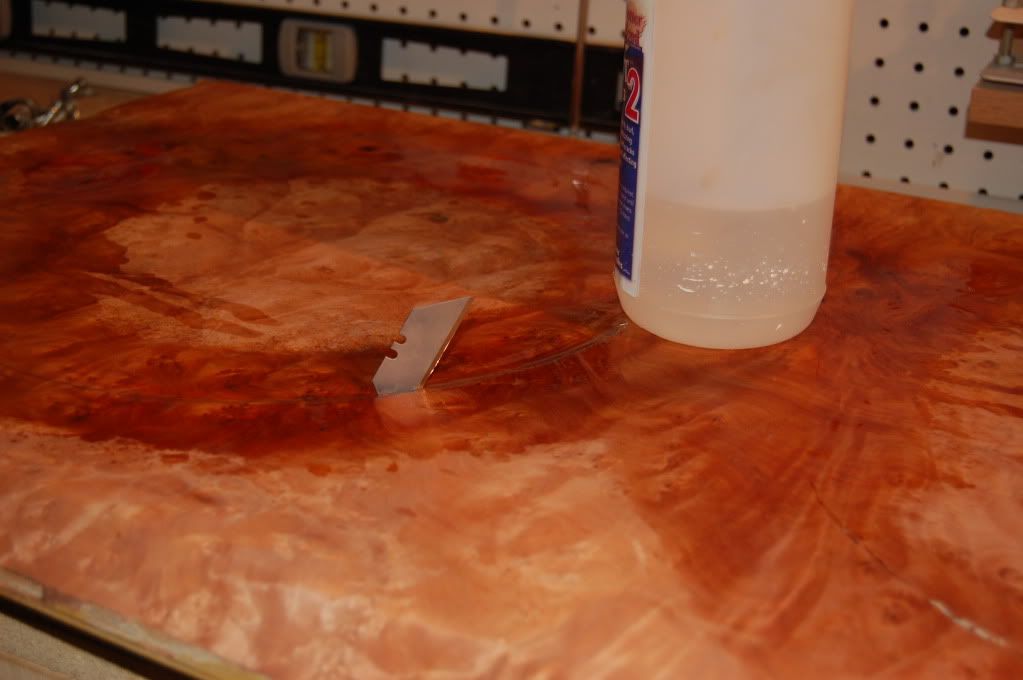

I don't have any photo's of the actual veneering process (yet....since it's being done at another fellows house), but after the veneer/vacuum press, here's what comes out.

The darker areas are where I've soaked the driver cutouts so I can run a razor blade through it without as much 'chipping' of the wood.

The baffles are three layers of plywood thick. It is necessary to place the driver cutouts back in the holes so the vacuum press doesn't shatter the veneer.

Note to self: Next time, veneer first, then do the router work. Ugh...

That's about enough typing for tonight, the rest of the pictures should speak for themselves.

Tony requested the side braces be taller, and with a radius inside the 'crotch' area.

Here's the second prototype, on the left. He didn't care much for the first generation on the right.

That's enough for this weekend..... "Bob out".....